Bayaanka Asturnaanta

Alumina (al2o3) Substrate hadda waa sida ugu badan loo isticmaalo, uguna macquulsan waxyaabaha sunta ah ee sunta ah ee 'walxaha' ee 'ugu fiicnaa'. Waxay bixisaa dahab koronto oo aad u fiican, xasillooni kiimiko, jireed heerkul ah, soo noqnoqoshada sare iyo waxqabadka kale ee dhameystiran. Goobta warshadaha otomaatiga ah, baahida loo qabo in alumina of offstrates-ka dhoofinta ay sii kordhayeen sanadkiiba sanadka ay sabab u tahay horumarka degdegga ah ee warshadaha.

IGBT waa mid ka mid ah aaladda ugu weyn ee aaladaha elektiroonigga ah ee casriga ah, waana caalamka loo aqoonsaday inuu yahay a Inta badan wax soo saarka wakiil ee kacaanka seddexaad ee tikniyoolajiyadda korantada elektiroonigga ah. IGBT waa aaladda ugu muhiimsan ee beddelka tamarta iyo isu-gudbinta, kaas oo hagaajin kara korantada, soo noqnoqda, soo noqnoqoshada, iwm. Moodooyinka Igbb ee Igbb ee Igbt, sunta alumina ee almuminic -ka dhoofinta ayaa ah kuwa ugu adduunka ee lagu isticmaalo. Si kastaba ha noqotee, sababtuna tahay jiritaanka kuleylka ee hoos udhaca ah ee al-ka-hoosaadka al -2o3 ee isku-darka iyo ciyaarta saboolka ah ee ay ku dhegan yihiin ee ballaarinta kuleylka kuleylka ee silikoon, kuma haboona agabka tackeught-ka korantada sare.

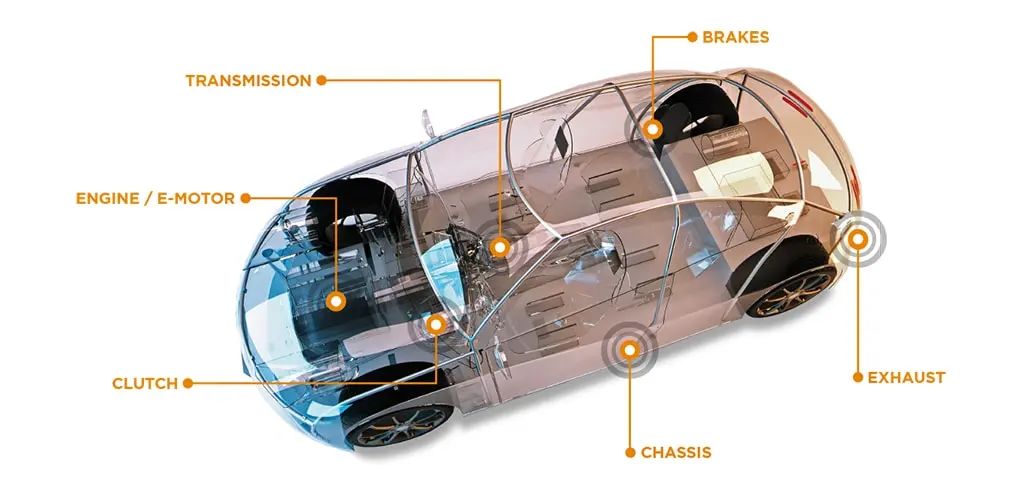

Dareemayaasha baabuurta waxay u baahan yihiin qaybaha inay yihiin in lagu dabaqi karo jawiga adag ( (heerkul sare, gariir, huurka, gaaska, gaaska, gaaska iyo sidoo kale waa inay lahaadaan miisaan fudud, iyo sidoo kale . xoogga dib-u-soo-saarka wanaagsan, iyo tirada wax soo saarka ballaaran Qalabka dhoobada dhoobada ah ayaa si buuxda u buuxin kara shuruudaha kore, oo matalaya codsiga Liirada, kamaradda, mawjadda milimitir iyo wixii la mid ah.

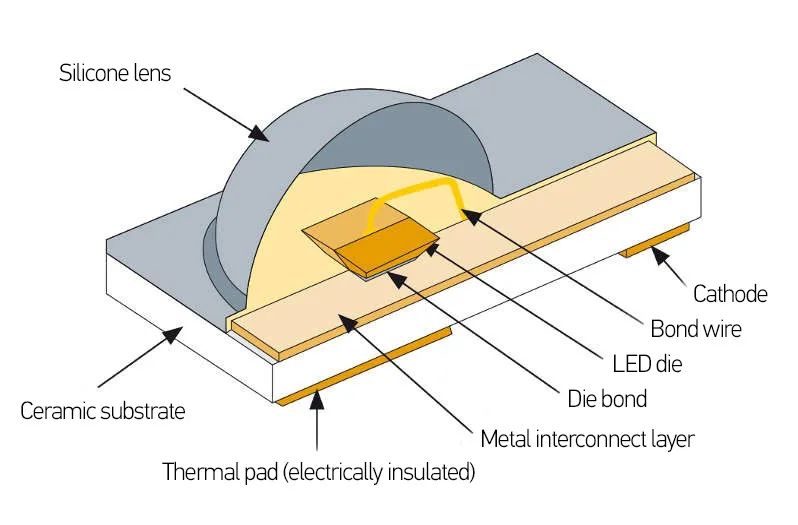

Sanadihii la soo dhaafay, tikniyoolajiyadda nalalka ee hogaaminta ayaa si ballaadhan loo adeegsaday wax soo saarka baabuurta, sida nalka tooska ah, sida nalka, tusaha, nalalka jawiga, soo bandhiga nambarka dib u dhaca iyo wixii la mid ah. Awoodda sare ee hogaaminta, dareenka badan ayaa loo baahan yahay in la siiyo mushkilad kululaynta kuleylka - haddii kuleylka ay ka dhashaan qalliinka hogaamisa aan si hufan loo kala firdhin karin, waxay ku dambayn doontaa heerkulka isugeynta, ee aan u horseedin oo keliya depid suuf ka mid ah waxtarka iftiinka leh ee la keenay, laakiin sidoo kale nolosha aaladda hogaamisa. Waqtigan xaadirka ah, isticmaalka sunta alumina chomicic kaliya maahan kaliya qiimaha, laakiin sidoo kale wuxuu si hufan u kala bixi karaa iyo soosaarka bey'adda sare, cufnaanta sare, sagxad sare, oo salka sare ah loo adeegsaday dhulka hogaaminaya.

In kasta oo dhoobada alumina uu la kulmi karo shuruudaha adag ee taageeraya iyo shaqada caabbinta nabaad-guurka deegaanka, Ficilka iyo horumarka dhabta ah ee uu yahay mid hooseeya, hagaajinta tayada sheybanka substrate ayaa lagama maarmaan ah si si wanaagsan loo buuxiyo shuruudaha horumarka warshadaha elektiroonigga ah , isaga oo ka faa'iideysanaya tayada shey ceyriinka ah ee al2o3 budada, kor u qaadida qiimaha guryaha, iyo doorashada geedi socodka ugu horreeya ee wax soo saarka ayaa la qaatay.

Ka sokow xulashada alaabada ceyriinka, sameynta iyo geedi socodka guska ayaa sidoo kale ah qodob muhiim ah oo ku saabsan go'aaminta guusha ama guuldaradii. Marka laga hadlayo tikniyoolajiyadda wax lagu durayo, gogosha la isku duro, saxaafadda qalalan iyo wasakhda tuurista ayaa badanaa la isticmaalaa, laakiin hufnaanta wasakhda duritaanka ayaa aad u sarreysa, laakiin way adag tahay in la sameeyo warqad-cabbir. Cufnaanta badeecada ee saxaafadda qallalan waa mid sare, dabaqyada ka mid ah substrates waa fududahay in la dammaanad qaado, laakiin hufnaanta wax-saarka ayaa hooseysa, oo kharashka ku sareeya, iyo diyaarinta sunta ah ee khafiifka ah ayaa adag. Cast-ka waa mid labalaab ah oo ah waxtarka wax soo saarka ee sarreeya iyo khafiifka-dhuuban, laakiin way fududahay in la curyaamiyo inta lagu guda jiro cafiska sababtoo ah cufnaanta hoose ee billicaan. Sidaa darteed, si loo wanaajiyo heerka badeecada heer sare ah ee sunta-weyn, warshadaha ayaa diiradda saaraya kobcinta hababka guska iyo xulashada dadaalka lagu daro.

Marka la soo koobo, marxaladda baaritaanka baabuurta iyo horumarka iyo wax soosaarka ayaa ahaa mid ka badan qalabka sunta almuminiya, laakiin haddii warshadaha wax soo saarka ee gawaarida ay noqon doonaan kuwa aluminigis-ka oluminis-ka ah, alaabooyinka dhoobada tirooyinku waa la soo bandhigi doonaa oo loo adeegsaday gawaarida , dhinacyo badan oo ka mid ah alumina dhoobada ceyriinka ee ceyriinka ah, qiimeynta sheyga iyo tikniyoolajiyadda wax lagu isticmaalo ayaa loo baahan yahay in la sii wado in la baro.

LET'S GET IN TOUCH

Bayaanka Asturnaanta

Buuxi macluumaad dheeri ah si markaa si dhakhso leh ula xiriiri karto

Bayaanka Asturnaanta