Bayaanka Asturnaanta

Waqtigan xaadirka ah, kormeerka ugu weyn ee daboolida substrate-ka dhoofinta ee dhawaaqa muuqaalka, kormeerka astaamaha, kormeerka kuleylka, kormeerka guryaha ee korantada, guryaha baakadaha (waxqabadka baakadaha) hubinta iyo kormeerka isku haynta

Baadhitaanka muuqaalka ee substrates-ka dhoofinta waxaa si joogto ah loogu sameeyaa microscopy-ka muuqaalka ah ama indhaha, oo inta badan ay ku jiraan dildilaaca, godad, xoqitaanno dusha sare ee lakabka birta, gogosha iyo cilladaha kale ee tayada leh. Intaas waxaa sii dheer, cabirka dulucda ee sunta, dhumucda lakabka birta, basaasnimada (cawjada) ee substrates, iyo saxsanaanta garaafka ee dusha sare ee substrates ayaa loo baahan yahay in la tijaabiyo. Gaar ahaan isticmaalka isku-darka flip-chip-ka, baakadaha cufnaanta sare, basaasnimada dusha sare ayaa guud ahaan looga baahan yahay inay ka yaraato 0.3% cabbirrada.

Sanadihii la soo dhaafay, horumarka joogtada ah ee tikniyoolajiyadda kombiyuutarka iyo tikniyoolajiyadda howsha sawirka, ku dhawaad dhammaan soosaarayaasha ayaa siiya wax badan oo fiiro gaar ah leh oo ah tikniyoolajiyadda aragtida macdanta iyo tikniyoolajiyadda aragtida , iyo hababka ogaanshaha iyo qalabka ku saleysan aragtida mashiinka si tartiib tartiib ah ayey u noqdeen si loo wanaajiyo tayada wax soo saarka iyo hagaajinta dhalidda. Sidaa darteed, adeegsiga kormeerka aragga ee mashiinka ee ogaanshaha substrate dhoofinta ayaa hagaajin kara hufnaanta ogaanshaha hubinta iyo yareynta qiimaha shaqada si ku habboon.

Guryaha farsamada ee 'Coapertrate-ka' ee Timamamka ayaa inta badan tixraacaya xoogga isku xirka ee lakabka saliidda birta, taas oo muujineysa xoogga isku xidhka lakabka birta iyo sunta dhoobada, oo si toos ah u go'aamiya tayada xirmada aaladda xigta (xoogga adag, iwm.) . Xoogga xidhiidhka ee isku-darka dhoofinta ee ay diyaariyeen habab kala duwan ayaa aad u kala duwan, iyo jaangooyooyinka diyaaradda ee diyaaradda (sida TPC, DBC, iwm, iwm, iwm, iwm, iwm. Iftiinka xidhiidhka ahu waa sarreeyaa. Marka lagu daro substrate-ka 'choprate-ka' ee uu diyaariyey habka heerkulka hooseeya (sida substrate-ka yar), xoogga 'Van der Wals' iyo xoog qaniinyada Van der iyo xoog makaanikada ee u dhexeeya lakabka birta iyo sunta ceymiska ee dhoobada ah ayaa inta badan ah, oo xoogga xirashada ayaa hooseeya.

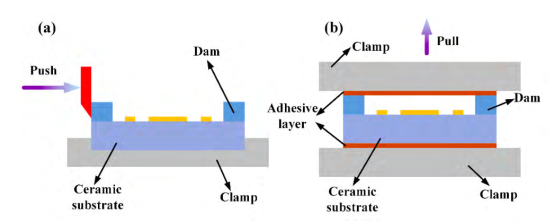

Qaababka tijaabada ah ee xoogga itaalka ka-hortagga dhoofinta ee 'Substrate' waxaa ka mid ah:

1) Qaabka cajaladda: cajaladdu waxay ku dhowdahay dusha sare ee lakabka birta, oo roller caag ah ayaa lagu duudduubay si looga saaro xumbada dusha sare ee isku xidhka. 10 ilbidhiqsi ka dib, ku dheji cajalad si xiisad ah oo kacsan lakabka birta, oo tijaabi in lakabka birta laga saaro substrate. Qaabka cajaladdu waa hab tijaabo oo tayo leh.

2) Habka qudhmay: Xulo silsilad bir ah oo leh dhexroor ah 0.5mm ama 1.0mm ama 1.0mm, weld si toos ah u dulsaarka birta ah oo ku dhexjirta jihada birta ah oo ku yaal jihada toosan ee xiisadda mitirka.

3) Habka xoogga diirka: lakabka birta ee dusha sare ee dusha sare ee dusha sare ee dusha sare ayaa la galiyay Xawaaraha wareejinta ayaa loo baahan yahay inuu noqdo 50mm / min iyo inta celcelis ahaan cabirka ah waa 10 jeer / s.

Guryaha kuleylka ee substrate-ka dhoofinta inta badan waxaa ka mid ah wanaajinta kuleylka, iska caabinta kuleylka, isku-darka kuleylka kuleylka iyo iska caabinta kuleylka. Qeybta Tixraaca ee dhoofinta ayaa inta badan door ku qaadata kuleylka kuleylka ee baakadaha aaladda, sidaa darteed horumarka uurka ku jira waa tilmaan farsamo muhiim ah. Caabbitaanka kuleylka ayaa inta badan tijaabada ah in sunta 'dhoofinta' ay ka go'antahay heerkulka sare, in lakabka safka birta dusha sare uu yahay mid kacsan yahay ama kala go ', iyo ha ahaado gudaha.

Wadahadalka kuleylka ee 'Clomer-ka' ma aha oo kaliya laxiriira qaab-dhismeedka kuleylka ee sheyga ee substrate-ka dhoofinta (iska caabinta kuleylka jirka), laakiin sidoo kale waxay si dhow ula xiriirtaa xidhiidhka xidhiidhka maaddada (Interface La xiriir iska caabbinta kuleylka). Sidaa darteed, tijaabiyaha kuleylka caabbinta kuleylka (oo cabbiri kara iska caabinta kuleylka jidhka iyo iska caabinta kuleylka kuleylka ee qaabdhismeedka lakab-ka-dhigyada badan) ayaa si wax ku ool ah u qiimeyn kara wada-shaqeynta kuleylka ee 'Cloumic'.

Waxqabadka korantada ee substrate-ka dhoofinta inta badan waxaa loola jeedaa bal in lakabka birta ee hore iyo dhabarka dambe ee substrate-ka uu sameeyo (ha ahaato tayada gudaha ee godku uu fiican yahay). Sababo la xiriira dhexroor yar oo ka mid ah godka substrate-ka DPC ee DPC, waxaa jiri doona cilado ay ka mid yihiin kuwa aan la buuxin, porods-ka iyo si ay u buuxiyaan godad korantada ah, tijaabadu (tacaliye) iyo tijaabada irbadaha ee duulaya (tiro ahaan, raqiis ah. ) guud ahaan waxaa loo isticmaali karaa in lagu qiimeeyo tayada daloolka ee substrate-ka dhoofinta.

Waxqabadka baakadaha ee baakadaha ee 'Cloumic' ee 'Cloumic' inta badan waxaa loola jeedaa deganaashaha iyo ciriiriga hawada (oo ku xaddidan sunta saddex-cabbir isku-darka ah). Si loo wanaajiyo xoogga xidhitaanka ee siligga rasaasta, lakabka birta leh waxqabadka alxanka oo wanaagsan sida AU ama AG waxaa guud ahaan ah korantada ee lakabka birta ah ee sunta ceyriska (gaar ahaan xarkaha alxanka) si looga hortago oksidation iyo hagaajinta tayada xidhitaanka ee siligga rasaasta. Daryeelitaan ayaa guud ahaan lagu cabiraa mashiinnada almunium ee al-aluminium-ka iyo mitirka xiisadda.

Chip-ka waxaa lagu dhejiyay daloolka isku-dhafka ah ee 3D ee dhoobada ah, daloolka waxaa lagu daboolay saxan daboolida (bir ama galaas) si loo ogaado xirmada hawada ee aaladda. Hawo-haqadu hawada cagta ee biyaha iyo walxaha alxamida ayaa si toos ah u go'aamisa hawada hawada ee xirmada aaladda, oo hawada hawada ku adkaysata ee sunta saddexda-cabbir ee isku-dhafka ah ee ay diyaariyeen habab kala duwan ayaa ka duwan. Saddexda qaybood ee isku-dhafka ah ayaa inta badan loo isticmaalaa in lagu tijaabiyo hawada hawada cagaaran ee biyaha iyo qaabka, iyo hababka ugu waaweyn waa gaaska gaaska iyo fiilo-yaasha dheelitirka ah.

Isku-kalsoonaanta ayaa inta badan tijaabiya waxqabadka isbeddelka substrate-ka ee jawiga gaarka ah (heerkulka sare, huurka sare, kaydinta heerkulka, oo ay ku jiraan kuleylka saboolka ah, ku-meel-gaarka ah, shoogga kuleylka, shoogga kuleylka, Iska caabbinta qaddarka, iska caabbinta, gariirka soo noqnoqda, iwm. Sawirka mikroskooska dhawaaqa (Sam) iyo baaxadda Raajada (raajada) waxaa loo isticmaalay in lagu falanqeeyo kooxaha ka ganacsada iyo ciladaha.

LET'S GET IN TOUCH

Bayaanka Asturnaanta

Buuxi macluumaad dheeri ah si markaa si dhakhso leh ula xiriiri karto

Bayaanka Asturnaanta